MIL-PRF-62410B(AT)

h. US.

3.6 Workmanship. Workmanship shall be of the quality necessary to produce tube

assemblies free from defects which may affect their serviceability or reduce, limit, or

compromise performance. Unless a finer finish is specified on drawings, sealing surfaces shall

be smooth except that annular tool marks up to 100-microinch roughness height rating (RHR), as

specified in ASME B46.1, will be acceptable. All other machined and bar stock flats shall be of

uniform quality, condition, and shall not exceed 250 RHR (see 4.7.2).

3.7 Parts. Contractor shall supply a list and necessary data for replacement and spare

parts. The contractor shall also assure that parts can be purchased using the contractors product

drawing(s) and that the hardware can be built from the drawing package.

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are

classified as follows:

a. First article inspection (see 4.2)

b. Conformance inspections (see 4.3)

4.2 First article inspection. Unless otherwise specified (see 6.2), first article inspection

shall be performed on three tube assemblies when a first article sample is required (see 3.1).

This inspection shall include the examinations of 4.4 (see Table IV and the tests of Table V).

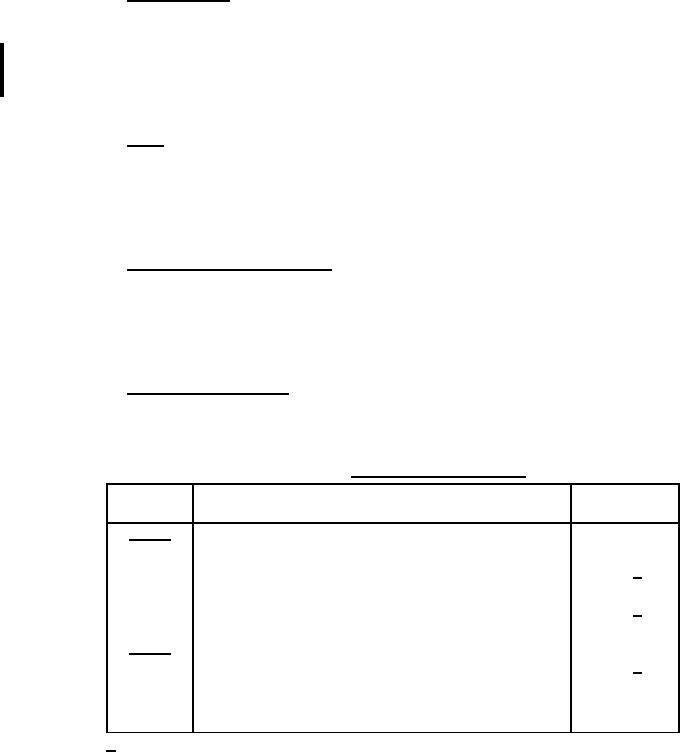

TABLE IV. Classification of defects.

Method of

Category

Defect

examination

Major

101

Incorrect or faulty materials (see 3.2 thru 3.2.3)

Visual

102

Dimensions affecting interchangeability, not within

SIE 1/

tolerance (see 3.3 thru 3.3.5).

103

Construction not within tolerance (see 3.3 thru 3.3.5).

SIE 1/

Minor

201

Dimensions not affecting interchangeability, not

SIE 1/

within tolerance (see 3.3 thru 3.3.5).

202

Incorrect or illegible marking (see 3.5).

Visual

203

Poor workmanship (see 3.6).

Visual

1/ SIE = Standard Inspection Equipment.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business