MIL-PRF-62410B(AT)

THREADS MUST BE COMPATIBLE WITH FITTING ENDS PER

SAE-AS33514 OR EQUIVALENT.

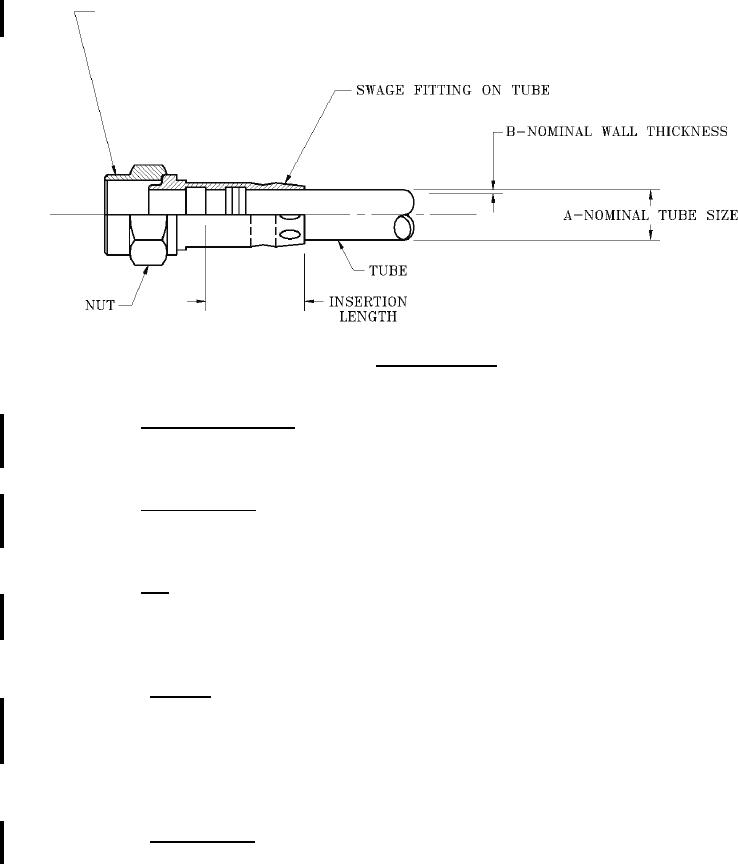

FIGURE 2. Separable fitting.

4.7.7 Tube insertion length. To determine conformance to 3.3.3, inspection shall be

performed using the tube insertion tool (gage) (see 4.7.4b) to verify the tube insertion length into

the fitting (see Figure 2) is as specified for the applicable tube size in Table II.

4.7.8 Tube bend radii. To determine conformance to 3.3.4, the tube assembly bend radii

shall be inspected for conformance to requirements of SAE AS33611 unless otherwise specified

on the detailed part drawing.

4.7.9 Nut. To determine conformance to 3.3.5, the nut shall be checked for thread size

with an appropriate go/no go thread plug gage and a functional mating performed with the

applicable fitting (see SAE AS33514). The connecting nuts of the assembly shall be examined

for being captive yet have the ability to swivel freely.

4.7.10 Leakage. To determine conformance to 3.4.1.1, connect the tube assembly to a

pressure supply unit (see 4.7.4.c). Utilizing an appropriately sized fitting (see SAE AS33514),

tighten the connecting nuts. Fill the tube assembly with test fluid and cap the open end after all

air is removed. Pressurize slowly from 0 psig to 1650 psig (0 MPa to 11.37 MPa) while

monitoring the assembly from behind a protective enclosure. There shall be no evidence of

external leakage or permanent deformation.

4.7.11 Proof pressure. To determine conformance to 3.4.2, connect the tube assembly to

a pressure supply unit (see 4.7.4c), then tighten connecting nuts of the assembly. Fill the tube

assembly with test fluid and cap the open end after all air is removed. Pressurize at one-third of

rated pressure increase per minute until 3000 psig (20.7 MPa) proof pressure is attained. This

pressure shall be maintained for a 5 minute period while monitoring the assembly from behind a

protective enclosure. There shall be no evidence of external leakage or permanent deformation.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business