MIL-PRF-62410B(AT)

3.2.1 Recycled, recovered, or environmentally preferable materials. Recycled,

recovered, or environmentally preferable materials should be used to the maximum extent

possible, provided that the material meets or exceeds the operational and maintenance

requirements, and promotes economically advantageous life cycle costs.

3.2.2 Tube. The tube shall be a corrosion-resistant material and meet the mechanical

properties as specified in Table I (see 4.7.1 and 4.7.2).

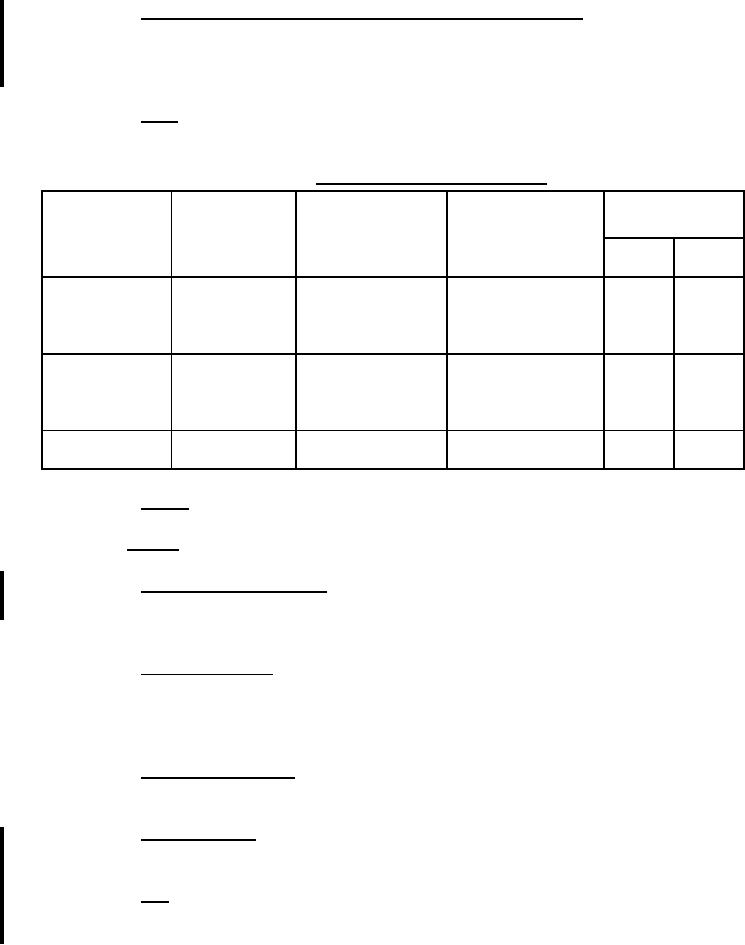

TABLE I. Mechanical properties of tubing.

Nominal outside

Nominal wall

Ultimate tensile

Yield strength

Elongation

diameter

thickness

strength

0.2 percent offset

min (percent)

Full

Strip

inch

(cm)

inch

(cm)

psi

(MPa)

psi

(MPa)

section

0.188 and less

0.016 and less

75,000

(516)

(0.477)

(0.0406)

120,000 max

(827)

---

---

35

---

over 0.016

75,000

(516)

105,000 max

(723)

30,000 min

(207)

35

---

Over 0.188 thru

0.010 and less

75,000

(516)

0.500

(0.0254)

115,000 max

(792)

---

---

35

---

(0.477 thru

over 0.010

75,000

(516)

1.27)

105,000 max

(723)

30,000 min

(207)

35

---

Over 0.500

All

75,000

(516)

(1.27)

100,000 max

(689)

30,000 min

(207)

35

30

3.2.3 Fitting. The fitting shall be of a corrosion-resistant material (see 4.7.1 and 4.7.2).

3.3 Design.

3.3.1 Fitting and tube assembly. The fitting and tube assembly dimensions shall be as

specified (see 6.2). The fitting configuration shall be in accordance with Figure 2 (see 4.7.2 and

4.7.5).

3.3.2 Fitting attachment. The fitting and the tube shall form a leak proof joint. If

swaging is performed, it is recommended that the fittings be swaged on the tube by applying

5500 pounds per square inch (psi) (38 Megapascals (MPa)) hydrostatic pressure on swaging dies

(see 4.7.2 and 4.7.6).

3.3.3 Tube insertion length. Before attachment, the length of the tube to be inserted into

the fitting shall be in accordance with Table II (see 4.7.2 and 4.7.7).

3.3.4 Tube bend radii. Unless otherwise specified on the detailed part drawing, all tube

bends shall be in accordance with SAE AS33611 (see 4.7.2 and 4.7.8).

3.3.5 Nut. The nut on the separable fitting shall have the same thread and hex size for

corresponding tube sizes in accordance with SAE J514 and shall mate with fittings specified in

SAE AS33514. The nut shall be captive and swivel freely on the assembly (see 4.7.2 and 4.7.9).

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business