MIL-DTL-25995D

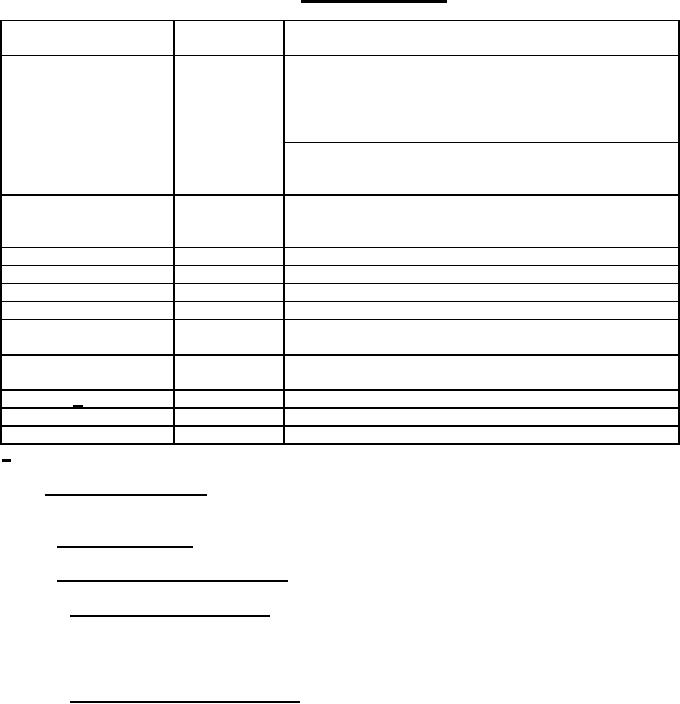

TABLE II. First article inspection.

Requirement

Inspection

Test paragraph or document

paragraph

Type A: (see 4.5.5)

ASTM B429/B429M (alloy -6061-T6 or 6063-T6)

Alloy type used

ASTM B483/B483M (alloy 3003-H18 or 3003-H112)

Chemical composition

ASTM B221 (alloy 3003-H112, 6061-T6, or 6063-T6)

Temper

ASTM B210 (alloy 3003-H18, 6061-T6, or 6063-T6)

Tensile strength

Type B: (see 4.5.5)

Type of heat treatment.

ASTM B241/B241M (alloy 3003-H18, 3003-H112,

6061-T6, or 6063-T6)

Visual and mechanical

inspection

Straightness

ANSI H35.2

Schedule (nominal)

Table I

Weight

Table I

Length

---

Allowable deviation

ANSI H35.2

from mean diameter

Allowable deviation of

ANSI H35.2

diameter

Leak test 1/

ASTM B210

Marking

Workmanship

1/ Not required for structural pipe.

4.6 Conformance inspection. For manufacturers that have successfully passed first article

inspections on going inspections shall consist of individual inspections.

4.6.1 Individual inspection. Individual inspection shall consist of the inspections specified in table II.

4.6.2 Sampling for individual inspections.

4.6.2.1 Sampling on a continual basis. On approval of the purchaser the producer may use a

system of statistical quality control for such examinations. Sampling for individual inspections shall be

shall be on a continual basis. Each pipe shall be examined to determine conformance to this

specification with respect to general quality and identification marking.

4.6.2.2 Sampling on a non-continual basis. For pipe sizes having a nominal weight of less than 1

lb/linear ft (.045kg/0.30 m), one test specimen shall be taken for each 1000 lb (453.59 kg) or fraction

thereof in the lot. For pipes having a nominal weight of 1 lb or more/linear ft (0.45 kg/0.30 m), one test

specimen shall be taken for each 1000 ft (304.80 m), or fraction thereof, in the lot.

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business